Glass Joint

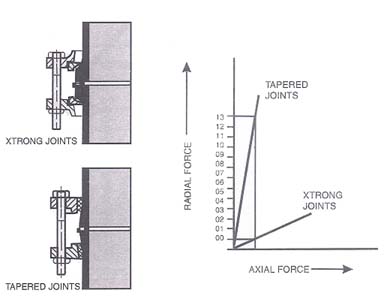

Tapered glass joints are predominantly used in Industrial Glass Equipment in India. This design has high ratio of axial force to redial force which frequently leads to breakage while making the joint. The higher breakage had deterrent effect on buyers.

It was recognized that a glass cylinder stands better in the application of axial force rather than in application of radial force. To exploit this feature of glass, we have come up with a new design of glass joints. It can be seen in the graph below that with the same axial force the effective radial force is 3 times smaller than is tapered joints.

Joints are practically may times stronger than conventional tapered joints as far as tightening of joints is concern. It is tested that a joint, does not break even at a tarque of 20Nm, as against tapered joints which starts breaking at 6-7 Nm tarque. At times it may happen that because of overtightening, a metal backing flange breaks or the threads of nut-bolts give way but glass joint remains intact.

Most of the old glass installations in India contain equipments with tapered glass joints. Glass joints are fully compatible with these tapered joints i.e. a joints equipment can replace another tapered equipment and vice versa in any existing unit. This interchangeability makes glass joint design more adaptable in Indian conditions and change over cost is negligible.

Glass joints which was mainly discovered as an “Answer to breakage” has found to have many other advantages like follows.

Usually all the glass joints possess a little or more ovality. Tapered joints are highly sensitive to ovality. However in glass Joint ovality hardly effects and gives no breakages.

b. Due to force and temperature inserts of backing flanges in tapered joints sticks to the glass as well as metal flange. The makes dismantling of unit more difficult and breakage prone. In glass joint design insert does not sticks and makes the dismantling safe.

c. In tapered joints long threaded bolts are because while tightening the soft inserts keep on compressing and slipping Over the tapered surface. The result in requirement of more Labour and time for tightening. The design of glass joints has reduced the length of tightening of bolts to less than a half and saves time and labour.

d. In Indian conditions of manufacturing glass joints are easy and fast to produces. This is because it require to process less length Of a raw glass tube.

With so many benefits and particularly low breakage risk, we have adopted design for all equipment manufactured by Shiva and its group companies. The glass joints is widely accepted and adopted by users as well as manufactures of Glass Equipments in India. DIMENSIONS OF GLASS JOINTS ENDS | DN | D | D1 | D2 | H1 | H2 | A | B | | 25 | 41 | 27 | 34 | 13 | 8 | 65 | 9 | | 40 | 56 | 40 | 49 | 14 | 9 | 65 | 9 | | 50 | 69 | 52 | 62 | 16 | 11 | 65 | 9 | | 80 | 98 | 79 | 91 | 18 | td>1265 | 9 | | 100 | 132 | 108 | 123 | 20 | 17 | 65 | 9 | | 150 | 184 | 159 | 166 | 22 | 19 | 65 | 9 | | 225 | 258 | 229 | 233 | 24 | 26 | 65 | 9 | | 300 | 340 | 308 | 315 | 24 | 26 | 65 | 9 | | 400 | 463 | 405 | 425 | 25 | 35 | 65 | 9 | | 450 | 535 | 455 | 499 | 25 | 50 | 65 | 9 | | 600 | 684 | 600 | 640 | 25 | 60 | 65 | 9 |

Contact Us

Shiva Scientific Glass Pvt. Ltd.

GH-8/350, Paschim Vihar,

New Delhi-110087(INDIA)

P : + 91 - 11 - 25261137

M : + 91 - 93101 85023, 98101 85023

E : boro.scientific@gmail.com

W : www.shivascientificindia.com

© Copyright2017. Shiva Scientific Glass Pvt. Ltd. Delhi, India

|